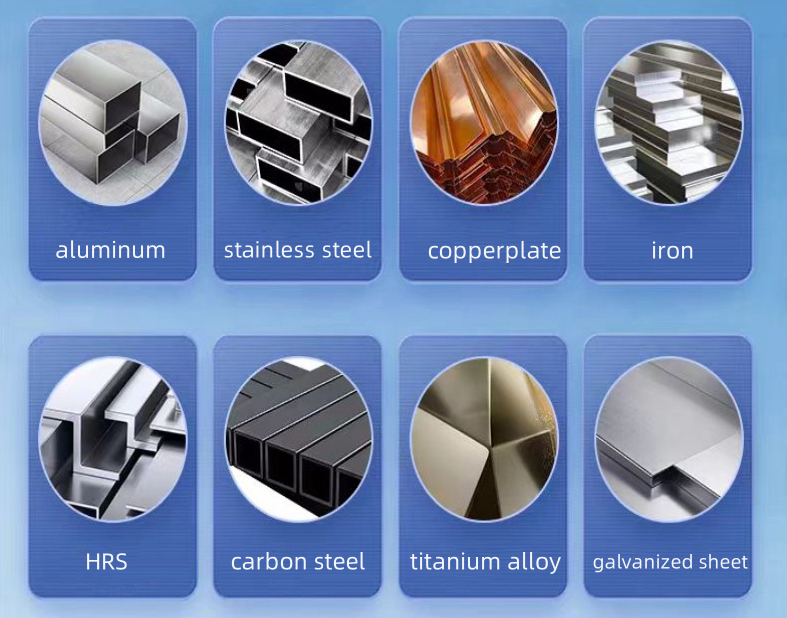

1. Insimbi engagqwali

Insimbi engagqwali ine-coefficient ephezulu yokwanda okushisayo, futhi ijwayele ukushisa ngokweqile ngesikhathi sokushisela. Lapho indawo ethinteke ekushiseni inkulu kancane, izodala izinkinga ezinkulu zokuguga. Nokho, ukushisa okukhiqizwa umshini wokushisela we-laser ophethwe ngesandla phakathi nayo yonke inqubo yokushisela kuphansi. Ngokuhambisana ne-thermal conductivity ephansi, izinga eliphezulu lokumunca amandla kanye nokusebenza kahle kokuncibilika kwensimbi engagqwali, ama-welds akhiwe kahle, abushelelezi futhi amahle angatholakala ngemva kokushisela.

2. Insimbi yekhabhoni

I-carbon steel evamile ingashiselwa ngokuqondile ngokuphathwa ngesandlaI-Fiber laser Welding Machine, umphumela uqhathaniswa nokushisela insimbi engagqwali, futhi indawo ethinteke ekushiseni incane, kodwa lapho i-welding medium ne-high carbon steel, izinga lokushisa elisele liphakeme ngokuqhathaniswa, ngakho kusadingeka ukushisela ngaphambi kokushisela. Ukushisa nokugcinwa kokushisa ngemuva kokushisela ukuze kunciphise ukucindezeleka nokugwema imifantu. Lapha singakhuluma ngomshini wokushisela obandayo. Insimbi ye-carbon emaphakathi nephezulu ingashiselwa noma ilungiswe ngesivinini esincane ngokushisela okubandayo kanye nocingo lokushisela lwensimbi. Mayelana nokulawula izinga lokushisa, ukulawulwa kwezinga lokushisa, nokulawula izinga lokushisa, umshini wokushisela obandayo ungafundisa i-laser welding ebanjwa ngesandla ngokuphumelelayo endaweni esele yokushisa ngemva kokushisela.

3. Die steel

Ifanele ukushisela izinhlobo ezahlukene zensimbi yokufa, futhi umphumela wokushisela muhle kakhulu.

4. I-Aluminium ne-aluminium ingxubevange

I-Aluminiyamu ne-aluminium alloys yizinto ezikhanyayo kakhulu, futhi i-porosity ingase ivele echibini elincibilikisiwe noma empandeni ngesikhathi sokushisela. Uma kuqhathaniswa nezinto zangaphambilini zensimbi, i-aluminium ne-aluminium alloys inezidingo eziphakeme zemingcele, kodwa uma nje imingcele ye-welding ekhethiwe ifanelekile, i-weld seam enezici ezifanayo zemishini njengoba isisekelo sensimbi singatholakala.

5. Ingxube yethusi neyethusi

I-thermal conductivity yethusi inamandla kakhulu, futhi kulula ukubangela ukungena okungaphelele kanye nokuhlanganiswa okuyingxenye ngesikhathi sokushisela. Imvamisa, izinto zethusi ziyashiswa ngesikhathi senqubo yokushisela ukusiza ukushisela. Lapha sikhuluma ngezinto zethusi ezincane.Umshini wokushisela we-laser ophethwe ngesandlacan ngqo Welding, ngenxa yamandla ayo kanzulu futhi isivinini Welding okusheshayo, kancane kuthintwa high conductivity ezishisayo zethusi.

6. Ukushisela phakathi kwezinto ezingafani

Umshini wokushisela we-laser ophethwe ngesandla ungenziwa phakathi kwezinhlobonhlobo zezinsimbi ezingafani, njengethusi-nickel, i-nickel-titanium, i-copper-titanium, i-titanium-molybdenum, ithusi-ithusi, i-carbon steel-copper ephansi nezinye izinsimbi ezingafani. I-laser welding ingenziwa ngaphansi kwanoma yiziphi izimo (igesi noma izinga lokushisa).

Umshini wokushisela we-laser ophathwa ngesandlaokwamanje iwumkhiqizo osetshenziswa kabanzi embonini yokushisela, ikakhulukazi ngoba nakuba le mishini ibonakala ibiza kakhulu, ingonga izindleko zabasebenzi kahle kakhulu. Izindleko zomsebenzi zabashiseli zibiza kakhulu. Ukusebenzisa lokhu Umkhiqizo uxazulula inkinga yokuqashwa okumba eqolo futhi okunzima kwama-welders. Ngaphezu kwalokho, umshini wokushisela we-laser ophethwe ngesandla uzuze ukunconywa ngazwi linye ezinkulungwaneni zamakhasimende ngenxa yempilo ende yesevisi kanye nokusetshenziswa kwamandla okuphansi.

Uma ufuna ukufunda okwengeziwe mayelana nokuhlanza i-laser, noma ufuna ukukuthengela umshini wokuhlanza we-laser ongcono kakhulu, sicela ushiye umlayezo kuwebhusayithi yethu futhi usithumele i-imeyili ngokuqondile!

Isikhathi sokuthumela: Dec-25-2024